Digatron and DSA have designed a solution for end-of-line testing for lithium battery production. The two companies developed a modular end-of-line test solution that allows customers to select pre-defined test regime modules per their requirements. Battery EOL Tester supports the entire workflow of EOL testing by offering customized communication and testing solutions, including electrical test,… Read more »

Author: Tom Lombardo

Punch Powertrain and Groupe PSA launch electrification joint venture

Punch Powertrain and Groupe PSA have launched a new joint venture to design, manufacture, and supply Punch Powertrain’s DT2 dual-clutch transmission for the next generation of hybrids. The business will initially supply Groupe PSA’s global operations, and aims to eventually supply other vehicle manufacturers. Elias van Wijk, previously CTO of Punch Powertrain, was named CEO… Read more »

Nissan achieves breakthrough in carbon fiber parts production

Carbon fiber reinforced plastic (CFRP) was once seen as an ideal body material for EVs, because of its high strength and light weight. It was used in the Tesla Roadster and the BMW i3, but fell out of favor because of its high cost. Now Nissan has developed a new production process that speeds up… Read more »

Consortium of auto suppliers launches multi-material EV battery casing project

German engineering firm AZL is joining with an international consortium of automotive suppliers to develop a multi-material battery casing. The 8-month product development will start with an international market analysis and a concept study in which different multi-material component concepts and production scenarios will be developed and evaluated with regard to their costs. Finally, a… Read more »

Accelerated electrode drying could reduce battery production cost

A new EPIC project coordinated by Karlsruhe Institute of Technology (KIT) is aimed at accelerating the drying of electrodes for lithium-ion batteries, increasing the energy efficiency of this process and reducing production cost. KIT says innovative electrode drying management can reduce the cost of battery production and improve environmental performance. The quality of Li-ion battery… Read more »

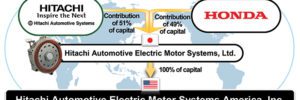

Hitachi establishes new EV motor company

Hitachi Automotive Systems recently established a spinoff—Hitachi Automotive Electric Motor Systems America—for the development, manufacture and sale of EV motors. The new company, led by President Shingo Nakamura, will utilize the existing 260,000 square-meter Hitachi office and manufacturing facilities in Berea City, Kentucky. Full production is expected to start in 2022, depending on the effects… Read more »

teamtechnik software applies Industry 4.0 optimization to End-of-Line EV system testing

End-of-Line (EOL) testing of EV powertrains now generates more data than ever, thanks to the ubiquity of smart sensors and the Industrial Internet of Things (IIoT). With a focus on testing and measurement, teamtechnik applies Industry 4.0 tools and techniques to optimize production and testing processes. Sometimes called “the fourth industrial revolution,” Industry 4.0 expands… Read more »

GM to debut wireless EV battery management system

General Motors will use an almost completely wireless battery management system (wBMS)—the first of its kind, according to GM—for production EVs. This wireless system, developed with Analog Devices, will allow GM to power many types of EVs from a common set of battery components. The wBMS is expected to drive GM’s Ultium-powered EVs to market… Read more »

New anode material could lead to safer batteries with long cycle life

Researchers at the Karlsruhe Institute of Technology (KIT) and Jilin University have investigated a promising anode material for future high-performance batteries: lithium lanthanum titanate with a perovskite crystal structure (LLTO). As the team reported in Nature Communications, LLTO can improve battery energy density, power density, charging rate, safety and cycle life without requiring a particle… Read more »

Mercedes and CATL team up on future battery technology

Mercedes-Benz and Contemporary Amperex Technology (CATL) are collaborating to create new battery technology for the high-volume electrification of Mercedes vehicles. The carmaker is accelerating its Electric First strategy, and plans to use carbon-neutral battery cells, modules and systems supplied by CATL. The agreement covers the full range of battery technologies, from cells to modules for… Read more »